In the ever-evolving landscape of safety footwear, ASTM boots stand out as an essential choice for those prioritizing protection, comfort, and durability in demanding environments. As we approach 2025, the importance of selecting the right safety boots has become more pronounced, not only for compliance with industry standards but also for ensuring optimal performance throughout the workday. This article explores the top ASTM boots that exemplify these qualities, empowering workers across various sectors to make informed decisions about their footwear.

With a focus on the latest advancements in materials and design, the upcoming selection of ASTM boots promises to enhance safety while offering unparalleled comfort. The integration of innovative technologies and user-centric features in these boots is transforming the way individuals experience protection in hazardous conditions. As we delve into the options available for 2025, it will become clear that the right pair of ASTM boots can significantly impact both productivity and overall well-being in the workforce. Embrace the new era of safety footwear as we unveil the best choices that meet rigorous standards and elevate your work experience.

Selecting ASTM-certified boots is critical for ensuring occupational safety, especially in environments where risks abound. ASTM, or the American Society for Testing and Materials, sets the standards for footwear performance, ensuring that boots meet specific safety requirements. These standards encompass various aspects such as puncture resistance, slip resistance, and electrical hazard protection, making them an essential choice for workers in construction, manufacturing, and other high-risk industries. By choosing ASTM-certified boots, employees can significantly reduce the likelihood of accidents and injuries that may arise from inadequate footwear.

Beyond just protection, comfort also plays a vital role in the selection of safety footwear. Occupational hazards can place immense strain on the feet, making it essential for boots to fit well and provide adequate support. ASTM-certified options are designed not only to meet safety benchmarks but also to enhance comfort, allowing workers to stay focused and productive throughout their shifts. This combination of safety features and ergonomic design ensures that workers can perform their tasks effectively without compromising on their well-being. Ultimately, investing in ASTM-certified boots is a proactive measure towards fostering a safer and more efficient work environment.

When choosing ASTM boots, prioritizing comfort and performance is essential for ensuring safety in various work environments. Comfort features often include cushioned insoles, breathable materials, and adjustable elements that cater to different foot shapes. Look for boots that have moisture-wicking linings to keep your feet dry during long hours on the job. A well-padded collar and tongue can also enhance comfort, reducing the risk of chafing or blisters.

Performance is equally crucial, as ASTM-rated boots must meet specific safety standards. Pay attention to the materials used in construction; lightweight yet durable options can provide the necessary protection without being cumbersome. The traction of the sole is vital to prevent slips and falls, especially in hazardous work areas. Additionally, reinforced toe caps and puncture-resistant soles add an extra layer of protection against workplace injuries.

Tips: Always try on boots with the socks you plan to wear at work to ensure the right fit. Walk around in them to test for comfort and support before making a final decision. Consider the specific demands of your job, such as exposure to chemicals or extreme temperatures, to make an informed choice that balances safety and comfort.

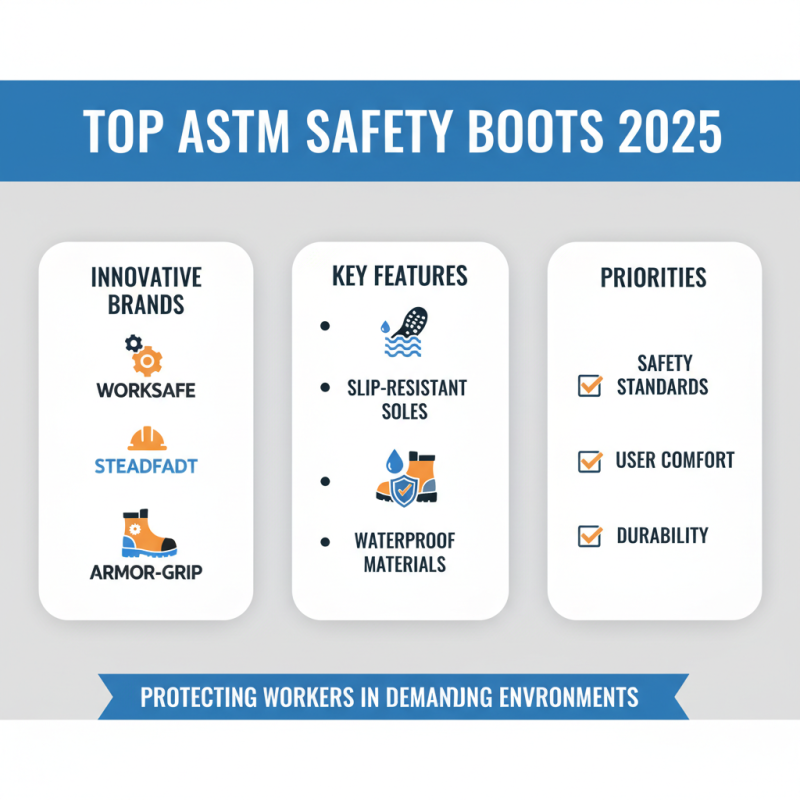

When it comes to selecting the best ASTM boots for safety and comfort in 2025, it’s essential to focus on the leading brands that are innovating within the industry. These brands invest heavily in research and development to ensure their products meet the highest safety standards while prioritizing user comfort and durability. Look for brands that offer features such as slip-resistant soles, waterproof materials, and reinforced toe caps, which are crucial for protecting workers in demanding environments.

Tips for choosing the right ASTM boots include considering your specific job requirements. If you work in wet conditions, opt for boots with waterproof qualities and good drainage systems. For environments where electrical hazards are a concern, ensure the footwear is rated for electrical safety. Moreover, pay attention to fit: a snug yet comfortable fit will enhance safety by preventing slips and falls.

Furthermore, it is worthwhile to examine customer reviews and ratings as they provide insight into the long-term performance of the boots. Often, feedback from fellow users highlights key comfort features and durability over time. Engaging with safety professionals or peer recommendations can also guide you toward the most reputable brands that prioritize worker safety without compromising on comfort.

In the evolving landscape of workplace safety footwear, ASTM-certified boots are increasingly integrating innovative materials and technologies to enhance user comfort and durability. According to a 2022 report by the National Safety Council, approximately 75% of workplace injuries are related to slips, trips, and falls, emphasizing the necessity for reliable protective gear. Modern ASTM boots utilize advanced materials such as composite toe caps, which offer protection comparable to steel while reducing weight. This shift not only eases the strain on workers' feet during long hours but also enhances mobility, as composite materials do not conduct heat or cold, maintaining comfort in extreme environments.

Furthermore, technologies such as moisture-wicking linings and antimicrobial treatments are becoming standard in the design of safety boots. A study published by the American Society of Safety Professionals highlights that about 30% of foot-related injuries occur due to prolonged exposure to moisture, leading to blisters and infections. Boots made with moisture-resistant uppers and breathable membranes help in reducing such risks. The incorporation of energy-absorbing insoles and slip-resistant outsoles further underscores the industry's commitment to worker safety and comfort, ensuring that employees can perform their tasks without the hindrance of inadequate protection. As the demand for smarter and safer footwear continues to rise, we can expect a greater emphasis on these technological advancements in ASTM safety boots.

To ensure the longevity of ASTM boots, regular maintenance is essential. Start with routine cleaning to remove dirt, mud, and other debris that can wear down materials over time. Use a soft brush or cloth to gently wipe the surface, and for deeper cleaning, consider using a specialized cleaner that’s compatible with the boot’s material. After cleaning, allow the boots to dry naturally, away from direct heat sources, to prevent cracking and deformation.

Additionally, conditioning the leather or synthetic materials is crucial for maintaining flexibility and durability. Applying a suitable conditioner can help protect the boots from moisture and prevent them from becoming brittle. Pay attention to the stitching and eyelets; treating them with appropriate waterproofing agents can enhance resistance to water and extend the life of the boots. Lastly, store your boots in a cool, dry place, and consider using boot trees to help maintain their structure when not in use. By following these maintenance tips, you'll ensure that your ASTM boots remain comfortable and reliable for years to come.

| Boot Model | Safety Rating | Comfort Features | Durability | Maintenance Tips |

|---|---|---|---|---|

| Model A | ASTM F2413-18 | Moisture-wicking liner, cushioned insole | Steel toe, rubber outsole | Clean regularly, apply leather conditioner |

| Model B | ASTM F2413-18 | Breathable mesh, padded collar | Water-resistant, composite toe | Store in a cool, dry place; avoid excessive moisture |

| Model C | ASTM F2413-18 | Ergonomic design, shock-absorbing midsole | Slip-resistant, durable leather | Regularly inspect for wear and tear, replace laces as needed |

| Model D | ASTM F2413-18 | Anti-fatigue technology, arch support | Oil-resistant outsole, reinforced toe | Use waterproofing spray; avoid harsh chemicals |

| Model E | ASTM F2413-18 | Lightweight design, comfortable lining | High abrasion resistance, sturdy upper | Limit exposure to extreme temperatures; clean with mild soap |